The working principle of the blasting system: the sand is stored in the blasting tank. When the blasting operation is carried out, the combined valve on the blasting tank acts to lift the sand-sealing support on the blasting tank and charge the blasting tank; At the same time, the sand valve under the sandblasting tank is opened, and the boost valve is opened; due to the pressure of the sandblasting tank, the sand is forced out from the sand inlet of the sand valve to the sand outlet, and the sand valve is pushed out through the boosted air flow The sand at the sand port is accelerated; the mixed flow of the accelerated sand gas flow passes through the sand blasting pipe to the high-speed sand blasting gun and further accelerates the sand in the high-speed sand blasting gun (boosting the gas flow to supersonic speed); accelerated The sand is sprayed onto the surface of the workpiece to be processed at a very high speed to achieve the surface and strengthening purpose of the sandblasting operation.

The working principle of the sand recovery, separation and dust removal system is: the airflow outside the blasting room enters the blasting room through the air inlet at the top of the blasting room, and then enters the blasting inside the blasting through the uniform flow plate on the top of the blasting room The working room forms a top-down air flow on the cross section of the blasting room, and passes the sand, dust, cleaning materials, etc. in the blasting room through the sand collection hopper at the bottom of the blasting room. Sand pit, manually push the sand material to the sand collection pit, the sand material is concentrated by the bottom horizontal screw conveyor, and the sand material is lifted by the bucket elevator to the sand inlet of the full curtain separator, through the full curtain separator, the abrasive Separated from dust and dirt, useful sand enters the blasting tank and continues to be recycled. Dust and dirt enter the dust removal system with the airflow, after the dust removal system is filtered, clean air is discharged into the atmosphere, and dust and dirt are stored in Wait for regular cleaning in the dust cylinder.

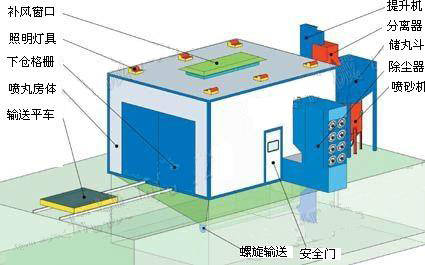

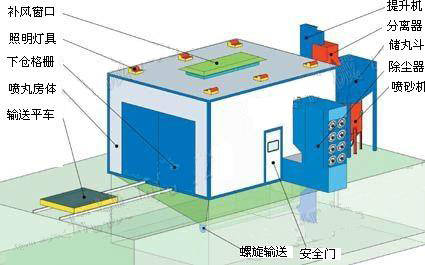

Equipment composition and structural characteristics

Sand blasting room consists of room body, electric roller gate, full curtain sorter, full room dust collector, chimney, fan, dust collector, sand blasting host, bucket elevator, horizontal screw conveyor, conveyor system (user Self-provided), pit steel structure, electric control system, lighting system, air-conditioning blasting suit, fixed working platform and other parts.

product description

Based on the introduction of foreign advanced technology, our company has developed and designed a fully automatic sandblasting room that can be designed and manufactured according to the customer's product characteristics and sandblasting requirements. Has the following advantages:

1. There is no need to design and manufacture complex foundations, saving foundation construction costs and greatly saving engineering costs;

2. There is no need to store a large amount of abrasives in the recycling spiral, and the abrasive recovery rate is high, which is convenient for cleaning and replacing the abrasives;

3. The main electrical components are all imported products, which have the advantages of stable performance, safety and reliability, long service life and simple maintenance;

4. There is high-definition visibility in the sand blasting room, and the room naturally supplements the wind to save energy consumption;

5. Double-stage dust removal, cyclone separator in the first stage, and filter-type dust removal system in the second stage, the total dust removal efficiency can reach more than 99.99%;

6. In the upper part of the front roof of the sandblasting room, there is a "sound and light alarm system", and in the sandblasting room, there is an emergency stop call button;

7. The electrical control of each system adopts interlock control. When one of the systems fails, the related systems stop working and the spray gun stops spraying;

8. The house body adopts architectural decoration design, with simple appearance, beautiful appearance, standardization, good noise reduction effect, and convenient installation.